spreader bar load test procedure|lifting beam spreader suspension : online sales Below-the-hook lifting devices such as spreader bars and lifting beams must be designed in accordance with ASME BTH-1 and are to be manufactured and used in accordance with requirements of ASME B30.20 which specifies .

web14 de mar. de 2023 · Miranda Cohen. @mirandacohenfit. Hip Thrust • My feet are shoulder width apart and my toes are slightly pointed out. I have my feet on plates so I can work a .

{plog:ftitle_list}

16 de mar. de 2023 · Contraband Police n'est actuellement qu'une version de démonstration et le jeu est encore en développement actifpour autant, il ne laisse pas grand-chose à désirer. Vous apprécierez peut-être les tâches subalternes consistant à vérifier des documents, à rechercher des incohérences et à tamponner des passeports.

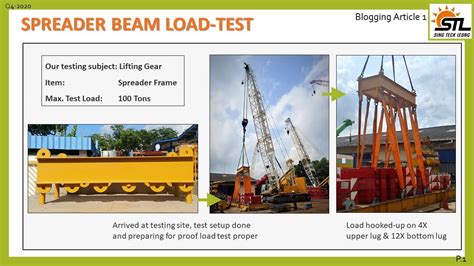

This article is a brief overview of what is covered by ASME BTH-1, particularly with respect to the design of spreader bars and lifting beams. Emphasis was made to focus on the areas of BTH-1 that apply to these devices.Test loads for all types of cranes and hoists indicator, a calibrated dynamometer, weights that proper weight. All load testing devices, i.e., load calibration label affixed in a conspicuous .The load test procedure is mostly performed on a static pull test. In most cases, a load that is 1.1 to 1.5 times the designated load is used. Barnhart has many tools and capabilities to meet the . The instructions should include performing a visual inspection, the procedure for assembling the spreader bar, the rigging requirements, and proper lifting techniques. It should also include specifications regarding examining the .

Hydro-Wates has extensive experience with spreader beam proof load testing services of the following types of spreader beams and below the hook lifting devices: Vessel Cargo Handling Beams. Container Handling Beams. Wind .Below-the-hook lifting devices such as spreader bars and lifting beams must be designed in accordance with ASME BTH-1 and are to be manufactured and used in accordance with requirements of ASME B30.20 which specifies .The guide contains information on various types of beams, how to ensure load stability, multi-purpose designs, standards, documentation requirements, design verification methods, load testing, beam markings, storage, safe use .All types spreader beams can proof load test using test weight water bags. DOOWIN proof load bags could perform well in load testing the following types of spreader beams and below the hook lifting devices: Vessel Cargo Handling .

They load test spreader beams quite often. Sometimes they have to make spreader beams to load test the spreader beams!!! They often do this using enormous water weights. They are often contracted just to perform the load testing of the spreader. I have seen some enormous spreaders that they tested used only once and then scrapped.February 9, 2004 Jeff Moser Director of Corporate Safety, Training & Education PFK-MARK III, Inc. 170 Pheasant Run Newtown, PA 18940 Re: §1926.251 - whether special test weights must be used for load tests; applicability of ASME inspection standards; whether manufactured (i.e., non-custom) lifting devices must be marked.Dear Mr. Moser:13 Load testing with weights 18 14 Load testing by means of an applied force 19 15 Verification of lifting beam with moving parts 20 . of the beam to connect to the load. A spreader, often called a spreader beam, is actually a strut loaded in compression. Typically a .

ASME B30.20 & BTH-1: Lifting Beam Design. Below-the-hook lifting devices such as spreader bars and lifting beams must be designed in accordance with ASME BTH-1 and are to be manufactured and used in accordance with requirements of ASME B30.20 which specifies requirements for marking, inspection, construction and operation. If you use a gantry crane with a custom lifting accessory, then, you'll want to test it with a load of precisely 125 percent of the manufacturer's limit. Going over 125 percent would violate 29 CFR 1910.179(k)(2), while failing to go right up .Bar-Worx performs load testing of BTH lifting devices such as spreader bars, end caps, lifting beams, and more. We also engineer load test procedures for all types of lifting equipment and various other components from a broad industry spectrum which require load testing services.

A spreader bar works by distributing a load across more than one point, increasing the stability and decreasing the load applied during hoisting. . the procedure for assembling the spreader bar, the rigging requirements, and proper lifting techniques. It should also include specifications regarding examining the condition of the load, not .Combi Stretcher Frame and Strap Stretcher • Set up the ARJO Load Test Kit as shown and fill the 6 x 25 liter water containers (part of ST120) with water and test to 160kg. NOTE: The six water containers filled with water equal the SWL of 160kg. . Service Procedures Service Procedure 20 Combi Spreader Bars 1) Visually check the jib for . The Crane Manufacturers Association of America standard CMAA Specification 78, section 4.7: Cites the load test requirements of OSHA 1910.179 and states a load test should be performed at a minimum of once every four years at 100% load with a pre-test and post-test inspection per periodic inspection guidelines, and there must be a written .The operator must test the brakes each time a load that is 90% or more of the maximum line pull is handled by lifting the load a few inches and applying the brakes. In duty cycle and repetitive lifts where each lift is 90% or more of the maximum line pull, this requirement applies to the first lift but not to successive lifts.

vacuum lifting beam spreader

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Of course the procedures for such testing would also need to comply with the manufacturer's recommendations. . or equipment such as large lifting fixtures, specially designed slings and spreader bars shall be 200% load tested (2 x Rating) annually with comprehensive inspection every 90 days. 100.9.4.5 Hoist anchorage including lift eyes, pad . When standard operating, maintenance, inspection, or test procedures cannot be followed as a result of radiation or radioactive contamination, toxic/hazardous chemicals or gases, or temperature extremes or other hazards: . three, or four pickup points located at the corners of the load, and without the use of a spreader bar, the forces at the . In a safety-conscious world where load testing is paramount, trust in a reliable solution like Water Weights® to ensure your lifting and spreader beams meet and exceed industry standards.

The proof load test, in its simplest form, is adding heavy loads to lifting or rigging machinery or load-bearing structures to see how much they can hold without issue. Skip to content ISO 9001:2015 Registered with Design MANY ITEMS IN .

We are able to conduct inhouse load tests of up to 1000MT; we can do a destructive test from 10kg onwards up to 1000MT. we have telemetry load cells, water bags and spreader bars For crane load tests

Beyond load testing, regular inspection and maintenance of spreader and lift beams are essential. Inspections should be conducted by qualified personnel who can identify any signs of wear, damage .4.7.2 Any item used to connect a load to a lifting machine (i.e. lifting beam, spreader bar, etc.); and/or. 4.7.3 Any item used to support a load (i.e. crane suspended personnel platform [man basket], powered platforms/sky climbers, etc.), but which is not in itself capable of providing any movement to raise or lower the load.

The model 1160 Spreader Bar is designed for use with rough terrain forklifts of adequate capacity to safely handle the load. It comes equipped with fork pockets that will accept up to 7” wide X 2 ¾” thick forks. Dual center holes provide hook points that also allows the spreader bar to be suspended from a crane. This The after load testing, by whatever test method is appropriate for what you want to see, and the final test results report might be interesting if they are made the first step in an ongoing, in-use, periodic inspection program for the spreader beams and .

Spreader Bar Lifting Device Calculations and Design (4/112) Description. Safe Working Load, SWL. Spreading Length. Safety Factor in Compression. . Safe Working Load Design . Calculation Preview. Submitted By: Michael Haise (engineerhk) Submitted On: 04 Mar 2016. File Size: 546.88 Kb. Downloads: 413. File Version: 1.0.

Proper attachment of the spreader bar to the load is non-negotiable. Verify that the attachment points on the load align with the spreader bar’s connection points. Hook or secure the attachments in a manner that ensures equal distribution of weight. An imbalanced attachment could lead to load tilting or instability during lifting.

Lifting Beams and spreader bars are fabricated devices for specific applications; therefore, you should never use them for a purpose that they are not designed for, unless you have an approval from the fabricator or supplier. You will be able to find an extensive range of designs that you can choose from depending on job specific requirements and the practicality, .The Test Facility has proven to be a faster/safer and more convenient way of performing load tests compared to the conventional way of testing. Besides the load test Facility, Yew Choon has build a gantry structure specifically designed for drop/impact testing structures after receiveing increasing requests from clients who need a facility .Supplied with: 1. Load Test certificate with 3rd party witness endorsement 2. NDT report for weldments 3. PE endorsed GA drawing 4. Assembly and usagee procedure/instructions. Optional: 1. Lifting sling sets 2. Annual recertification of work basket and lifting sling.

The Maxirig Telescopic Spreader Beam is designed for a variety heavy lifting applications. Designed to function as both a spreader bar in the 60°, 90° and 120° positions, it also can be used as a lifting beam from the centre lift (lug) position. The product is supplied certified to AS4991-2004 and includes a proof load test certificate and MPI welding report.

agile lifecycle and its impact on testing

spreader beam testing

webVDM Equipamentos de Segurança e Uniformes. VDM Equipamentos de Segurança e Uniformes.

spreader bar load test procedure|lifting beam spreader suspension